Specifications

Inside Diameter PX 15___

(GS,SS,16,20) PX18___

(GS,SS,16) PX25___

(GS,SS,20)

Weight per foot (lbs.) Min. Bend Radius (in.) Weight per foot (lbs.) Min. Bend Radius (in.) Weight per foot (lbs.) Min. Bend Radius (in.)

4 1.8 16.5 2.2 18 3.2 20

5 2.2 21 2.7 23 4.0 25

6 2.7 25 3.2 26 4.7 29.5

7 3.1 29.5 3.7 31.5 5.5 34.5

8 3.5 33.5 4.2 35.5 6.2 39

*For packed hose add 20% to minimum bend radius

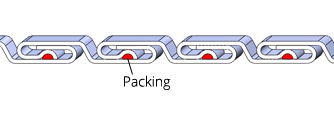

Available Packings

Packing Type Features Max Temp.

Low-Temp Elastomeric Max Pressure and Vacuum 200° F

High-Temp Elastomeric Max Pressure and Vacuum 500° F

Low-temp Fiber Economical 180° F

High-Temp Fiber Elevated Temperature 1000° F

Metal Extreme Temp. 800° F – 1200° F

When to Consider Packing:

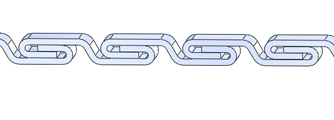

Interlocked metal hose, by the nature of its construction, is not pressure tight. However, pressure and media infiltration through the interlocked wall can be minimized by the insertion of one of a variety of packings into the wall during hose manufacturing. Packing consists of a continuous cord or strand of elastomer, or other material which is locked into a special channel between the interlocked hose wall layers. The choice of packing material is tailored to the demands of the specific application.