Within the industrial sector of Houston, every facility relies on industrial hose to contain immense internal forces. Because of this, understanding the different aspects of industrial hose pressure ratings and how they impact your facility’s operating procedures is vital for preventing hazardous situations. Aside from just preventing danger in your facility, using the correct pressure within your hose can protect your business from costly downtime and environmental damage. J.W. Roberts is Houston’s premier supplier of industrial hose, catering to the unique requirements of your facility. Use this blog to learn about the factors that contribute to pressure ratings and what goes into accurate, reliable selection for industrial facilities.

Fundamentals of System Pressure Ratings for Industrial Hose

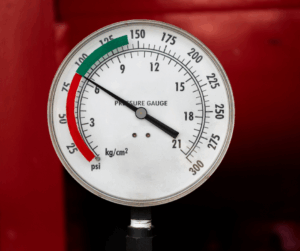

While a pressure gauge might offer a quick, surface-level look into what is happening within your hose, in an active industrial facility, the internal force is rarely a simple figure. To fully understand pressure ratings, first learn how pressure behaves, especially in the dynamic environments of oil and gas processing plants, chemical manufacturing, and other industrial facilities. Industrial hoses experience two primary types of pressure: static pressure, which exists at rest, and dynamic pressure, which results from flowing velocity and friction.

Under the umbrella of dynamic pressure, something known as transient pressure can also occur within industrial hoses. This specific event, which sometimes causes people to call it a water hammer, involves the pressure within a hose spiking or significantly dropping. These events can cause even a perfectly rated facility hose to fail. Because of this, accounting for non-continuous forces within a system is pivotal for preventing unexpected drops and spikes.

The most common non-continuous forces within industrial hose systems are vacuum and suction ratings. These are the opposite of positive pressure, otherwise known as working pressure, because these forces create compressive force that can threaten the structure of the hose. In the most severe cases, it can cause kinks to appear or for the hose to completely collapse in on itself. The best way to combat this occurrence is by including the failure point of both working and negative pressure when evaluating what rating you need for your facility’s hose.

Industrial Hose Ratings: The Primary Pillars

When it comes to hose integrity, it might seem extremely complicated. However, the truth is that hose ratings often boil down to three crucial aspects of the industrial hose rating system. These include: working pressure, burst pressure, and safety factor. Understanding how each rating functions and what makes them vital is integral for maintaining knowledge about your system and what keeps it safe:

- Working Pressure: This is defined as the maximum sustained pressure that a hose can handle consistently under normal operating conditions. As a general rule, the working pressure must be either equal to or greater than the maximum pressure of the system in order to be safe for the facility.

- Burst Pressure: The burst pressure rating is the amount of pressure that is expected to cause the hose to fully fail. We determine this rating through destructive testing to failure under safe and reliable lab conditions. What makes this different from the working pressure figure is that burst pressure is a laboratory value, not an operational limit.

- Safety Factor: This is the ratio found between working pressure and burst pressure, essentially known as the general margin of error. What makes this vital knowledge is that it accounts for manufacturing tolerances, system shocks, temperature changes, and industrial hose fatigue.

Understanding these specific functions is what makes J.W. Roberts the ideal partner for your industrial facility’s hose needs. We integrate our understanding of these functions and your specific needs to design a system that lasts and delivers optimal performance.

Real World Application: Factors That Degrade Hose Pressure Ratings

Environmental and mechanical stresses determine pressure ratings for industrial hoses, especially in bustling Houston facilities. This introduces the crucial factor of derating, which is the understanding that the true, consistent reliability of a hose is often much lower than the printed specification – meaning that operating safely is critical over cutting corners with specifications in every application.

Pressure ratings for industrial hoses are based on ideal, perfect conditions, but at J.W. Roberts, we strive to keep our clients safe and their facilities operating at maximum capacity. Because of these, we always take into account these key derating factors that might affect your industrial hose’s actual operational capacity:

- Temperature: Both external and internal heat can soften and weaken the reinforcement of industrial hose.

- Chemical compatibility: Incompatible fluids can dissolve, erode, or cause cracking within the inner tube wall. This severely compromises the system’s structural integrity.

- Bend radius and installation stress: When stress is concentrated, causing a hose to bend tighter than specified, it can cause damage to the reinforcement and result in kinking.

- External damage and abrasion: When the outer cover of an industrial hose is damaged, it can lead to premature failure or fatigue.

- Pulsation and impulse cycles: Sometimes, hoses that are correctly fitted for system pressure ratings can still fail, especially if the pressure is significantly lower than the allotted pressure for the hose, which may cause fatigue from contracting and expanding.

- Hose assembly and fittings: When a hose is improperly crimped, the pressure rating is compromised, making it imperative not only to adhere to pressure ratings but also to the manufacturer’s exact crimp specifications.

Because of the number of factors that cause derating, working with industrial hose professionals in Houston, like J.W. Roberts, is an integral aspect of prioritizing facility safety.

Selecting Correct Industrial Hose Pressure Specifications

Understanding the risk is one thing, but the final line of defense protecting your facility is our team at J.W. Roberts. The human element and fine-tuned expertise when it comes to industrial hose is often what makes the difference between safe, successful, and reliable operations and complete and expensive failure.

To select the correct hose for your industrial application in Houston, we consider the size, temperature, application, media, and pressure requirements of your specific needs. To select the correct pressure rating, all other specifications must be exact to ensure an optimal safety factor. When you decide to work with J.W. Roberts, you can rest easy knowing your facility is in good hands and that your industrial hose is reliable and ready to help you achieve your goals.

Putting Safety First: The Bottom Line on Industrial Hose Pressure Integrity

Hose specifications are something that must be completely accurate in order to project your team, your facility, and your results, as well as prevent costly downtime and large-scale accidents. Failing to prioritize pressure ratings can lead to detrimental failure. Because of this, working with industrial hose experts at J.W. Roberts is a non-negotiable for your operation.

We have been providing Houston facilities with high-quality, reliable, and cost-effective industrial hose since 1973. Let us help you achieve success within your field while keeping your facility safe from pressure spikes and drops. Contact us today for a free industrial hose estimate for your Houston facility.