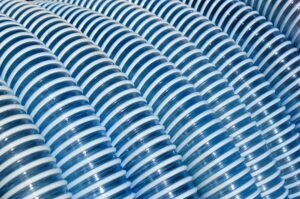

One of the best industrial hose options for many industries is PVC hosing. PVC offers a wide range of benefits, and the characteristics of the material can be adjusted for their intended application. Industrial PVC hose can be made in a variety of sizes and configurations and can work with existing industrial metal hose.

We’re experts in all aspects of industrial hose, from PVC to metal options. We can help you find the precise type of hose you need, and get it to you quickly. Contact our team at J.W. Roberts today.

What is PVC?

Polyvinyl chloride is a type of general purpose plastic that has a wide range of applications. While there may appear to be little difference between plastics that have carbon and hydrogen atoms and those that also have chlorine atoms, the addition of chlorine atoms makes a significant difference in how the plastic performs. Thanks to its chemical composition, there are many benefits to using PVC hoses, including its fire retarding properties, electrical insulation, versatility of use, and durability.

Easy Modification of Material Characteristics

PVC is excellent for industrial use as it is highly versatile. It is amorphous, so it mixes well with other substances, and its compound also hinders microbial growth. This increases its impact resistance, flexibility, and elasticity. PVC is also very responsive to coloring, printing, and adhesion, and does not require pre-treatment. Plus, when plasticizers are added, the material also has a rubber-like elasticity.

The ability to modify the properties of PVC to increase its heat or impact resistance makes it a strong choice for industrial hose in everything from hot water pipes to electrical connectors.

Fire Resistance

As a result of the chlorine content, the ignition temperature of PVC is as high as 455 degrees Celsius, even without additional retardants. Even if heat is sufficient to ignite PVC, it produces far less heat when burning than other types of plastic, helping to reduce the risk of fire spreading. While other materials may have slightly better electrical insulation, PVC’s inflammability makes it the material of choice for many applications that involve electrical cables, wire coverings, and tubing for power and telecommunications cables.

Chemical and Oxidation Resistance

As with other general purpose plastics, PVC’s main chain is composed of single bonds of carbon atoms, which makes it very resistant to chemicals. It is resistant to acid, alkali, and nearly all inorganic chemicals. Organic solvents also have difficulty dissolving PVC industrial hose, making it reliable and safe for certain operations such as chemical storage tanks, sewage pipes. and for plant piping.

PVC industrial hose also shows superior resistance to oxidation by atmospheric oxygen. The Japan PVC Pipe & Fittings Association took measurements of underground PVC pipes made 35 years ago and discovered that they exhibited no deterioration and had the same strength as new pipes. Similar results, showing little to no deterioration, were found when PVC products were recovered from vehicles that had been in use for well over a decade.

Strength, Stability and Durability – Industrial PVC Hose

Compared to other plastics, PVC industrial hose comes out on top in terms of tensile, bending, compressive and fatigue strength; impact strength is the only exception. PVC is also very stable, and it exhibits very little creep, which is when products deform over time due to constant pressure. This is because PVC has a very stable chemical structure with limited molecular motion, and it is much more stable than other plastics.

Let us help equip your operations with the best industrial hose options possible. Reach out to the experts at J.W. Roberts now.